Soaking Chamber

Purpose:

- An area to ensure Coolant and Engine Oil temperature meet the required value before proceed for testing.

Specifications:

| Temperature: | 25 ± 5 °C |

| Soaking Duration: | 6 – 36 hours |

| Coolant Temperature: | 25 ± 2 °C |

| Engine Oil Temperature: | 25 ± 2 °C |

Chassis Dyno Chamber

| Regulation: | Light Duty vehicle emission up to Euro 6D, WLTP (including NEDC, Malaysia Driving Cycle) |

| Vehicle to be tested: | Light duty vehicle 2WD, 4WD |

| Vehicle Wheelbase: | 1800-3400mm |

| Fuel Type: | Gasoline, Diesel, CNG, LPG |

| Engine to be tested: | Spark Ignition, Gasoline Direct Injection, Compression Ignition |

| Maximum Power: | 155 kW (207hp) |

| Maximum Speed: | 200 km/h |

| Maximum Axial Load: | 2500 kg |

| Chamber Temperature: | -7 °C – 60 °C |

| Solar Simulation System: | 1200 W/m2 (simulate weather condition in Malaysia) |

Observation and Control Room

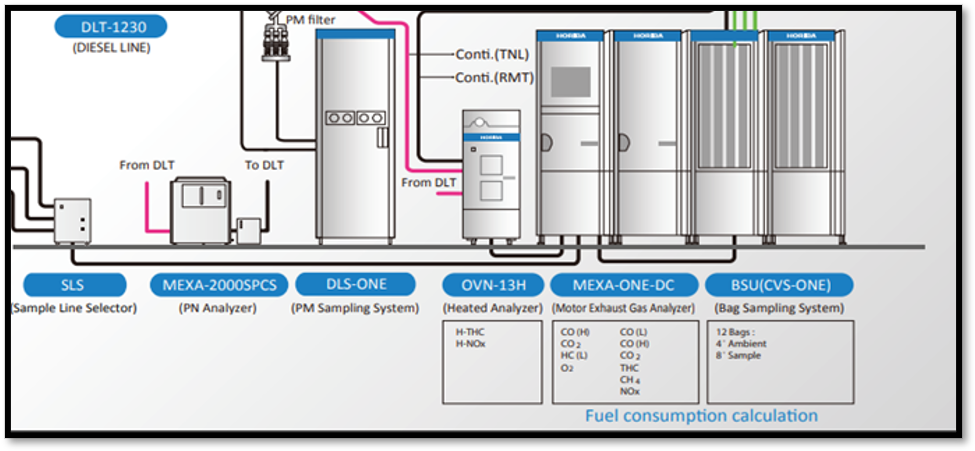

Emission Equipment Room

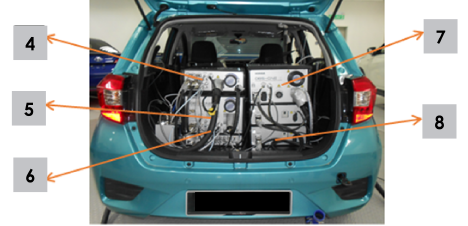

Portable Emission Measuring System (PEMS) for Real Driving Emission (RDE)

- Emission Hose

- PN Analyzer Hose

- Pitot Tube

4. Flame Analyzer (FA)

5. Gas Analyzer (GA)

6. Control Unit (CC)

7. Particulate Number Module (PN)

8. Power Supply Unit (PS) / Power Exchange Unit (PU)

Sealed Housing for Evaporative Determination (SHED) Chamber

| Model: | SHED – 511 |

| Regulation Applied: | Euro 6D – Temp, EVAP GTR No. 19, EPA |

| Maximum Test Vehicle Mass: | 3000 kg |

| Internal Chamber Dimension: | 3.0 m (W) x 6.95 m (D) x 2.3 m (H) |

| Rack Dimension: | 3.1 m (W) x 7.0 m (D) x 2.95 m (H) |

| Inside Temperature & Humidity: | 0-40 °C 80% RH |

| Door Mechanism: | Automatic Hydraulic System |

| Volume Absorption Unit: | Trapezoidal bag type, located at chamber ceiling |

EV Charger

| Brand: | ABB |

| Model: | Terra 54 50kW DC Charger |

| Connectors: | CSS, CHAde MO, Type 2 (AC/DC) |

| Dimensions (D x W x H): | 780 mm x 565 mm x 1900mm |

| Mass: | 350 kg |

| Charging Time (min) – 60 kWh BEV 400 VDC: – 90 kWh BEV 400 VDC: – 100 kWh BEV 400 VDC: | 50 70 80 |